Profi2M

CNC Vezérlő

(Micro-Step CNC Axis Driver)

Modified: 2009. szeptember 01. kedd

Discontinued!

| Content: |

| Introduction |

| Installation |

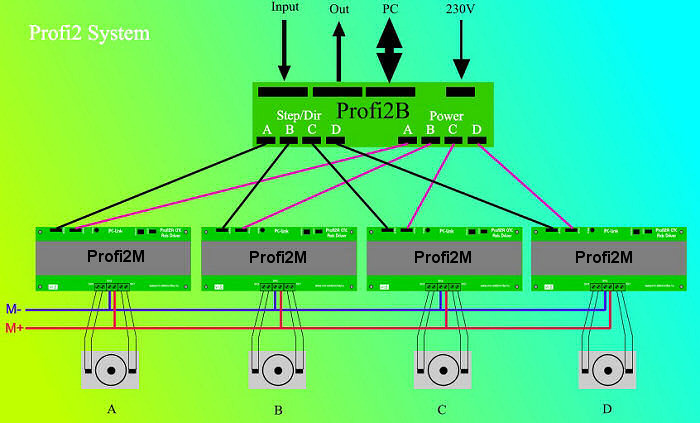

It is a modern, cheap, high-performance, micro-stepping, stepping-motor CNC control electronic equipment. This axis controller belongs to Profi2 CNC Controller family, which can be arranged depending on the demands from 1 to 4 axes for each base card because of its arrange-able build-up (Profi2B). By the use of suitable CNC control softwares (e.g. Mach3) two base cards can be used simultaneously, so CNC machines with maximum of 6 axes can be built.

Demo Video:

Profi2M.wmv (5.1MB)

Picture gallery:

(Click to zoom.)

Technical specifications (Config: 110):

- Step/Dir system, stepping motor CNC Controller,

- one axis for a card, modular, arrange-able build-up,

- 1 ; 1/2 ; 1/4 ; 1/16 adjustable, micro-steps,

- 2-phase, bipolar power transmission bridge (with uniform FETs),

- 2-phase, 2.3A - 9A, regulated, motor phase-current driving,

- Reduction of active heat production,

- Mixed mode current-decay (resonance-free running),

- 50V maximum motor power supply voltage,

- a Tuning factor of maxmimum 25-fold,

- 250 000 Step/sec signal processing speed,

- Thermal overload-protection,

- Constant torque control (constant motor-performance)(PWM),

- Reduced PWM noise,

- Sinusoid type current-regulation curve (reduction of motor resonances),

- Easy Setup (by jumpers + potentiometer trimmers, fast setup),

- Optimalised to Mach2 & Mach3,

- High-level noise protection (for industrial applications),

- Installed massive cooling,

- Two-sided partly SMD mounted PCB,

- Compatibility with Profi2B,

- etc.

![]() General

description:

General

description:

(Profi2M CNC Controller)

Profi2M is a arrange-able build-up, one-axis professional controller. In default build-up one Profi 2M Controller belongs to each motor (axis).

Between Profi2M Controller and the PC there is a Profi2B base card. The base card is the interface towards the printer port (LPT) of the PC (amplification and distribution of the signal). On the Profi2B base card the basic I/O ports (5 inputs and 4 relay outputs), as well as Step/Dir driven TTL outputs for 4 axes and the digital power supply of the system (+5V and +15V) can be found.

(Profi2B Base card)

According to the above-written things to a

Profi2B base card maximum 4 Profi2M

Controllers can be connected. The system with the above-mentioned build-up,

which uses one LPT port of a PC, can be a 4D (4-axis) CNC machine, which has 5

inputs (e.g. for end positions, for digitalizer peaks, for recording reference

points, etc.), and 4 relay outputs (e.g. for

Charge-Pump

protection, for controlling finishing motors, cooling, lubricating, etc.). If

more than 4 axes or I/O ports are demanded, then

the PC

must be extended with more LPT ports and Profi2B cards , and only the

capability of the CNC control programme will limit the system).

The the Profi2B base card was designed to

be able to work with max. 4 Profi2M cards.

(Build-up of the 4D system)

Profi2M Controller has a standard positive logic, it works with TTL-level Step/Dir signals, so movement-controllers made by other manufacturers (e.g. Maxstepper, USB-Step/Dir generator, RS232, etc.) can also be applied.

Type of the 2-phase stepping motors:

(Stepping motor)

- Bipolar motors,

- Unipolar motors (with bipolar connection),

-8-wire, universal motors (bipolar, with paralell connection).

About 40 % of torque difference can be measured between a

bipolar and a unipolar motor with the same electric parameters in favour of the

bipolar one. Therefore the use of bipolar motors is preferred.

The tuning factor* of Pofi2M Controller is , - depending on the inductivity of

the motor applied, - 10-25×(fold). This controller requires a tuning voltage of

minimum 6×(fold).

The smaller is the inductivity of the motor, the higher is the tuning factor

that can be applied. To determine the suggested maximum motor power supply

voltage, use the following table:

| Power supply voltage of motor: (voltage indicated on it) |

Recommended motor power supply voltage: (max. tuning voltage) |

|---|---|

| 1V | 20V |

| 2V | 40V |

| 3V | 45V |

| 4V | 45V |

| 5V | 45V |

| 6V | 45V |

| 8V | 45V |

| 9V | 45V |

| 10V | 45V |

| 11V | 50V |

| 12V | 50V |

| etc. | ... |

![]() Attention!

50V voltage must not be exceeded! Take care of possible voltage overrun of the

unloaded power supplies.

Attention!

50V voltage must not be exceeded! Take care of possible voltage overrun of the

unloaded power supplies.

The maximum motor power supply voltage that can be connected to

the controller is 50V! The continual load that can be handled by the power

transmission FET bridge is : 9A/phase! At a load near the maxmimum load an

intensive ventillation supported by fans must be provided.

The variable duty cycle PWM signal generated by the controller has a frequency

of 20kHz, so it will produce in the motors a voice that hardly can be heard by

human ears (a slight hiss or swish can only be heard).

Signals:

Power Ok LED: Signals that the power supply voltages are OK.

Overload LED: Indicates if there is any overload. It continually measures the temperature of the heat sink of the power transmission bridge and about over 70°C it prohibits the operation of the Controller.

Further developments:

- With the help of the DSP processor the Profi2M Controller

realizes a special current regulation, which varies depending of the phase

position and on the time.

The sinusoid type of the driving realizes a very smooth stepping in the

micro-stepping system, therefore the motor resonances decrease in a great

extent. It makes possible to increase the acceleration of the motor with about

30%. Because of the mixed mode decay current regulation the running quality is

surpassingly excellent (further increasing the efficiency of the reduction of

resosnance).

- The Controller has an easy setup. It means that only 4 jumpers and the nominal current of the motor (with the help of a potentiometer trimmer) must be adjusted before putting the equipment into operation and you may as well start to work. By the potentiometer trimmer the nominal current of the motor must be adjusted and a coarse adjustment is enough. The elctronics does need exact adjustment (it is linear and tolerant), so there is no need to check it by a measuring equipment!

- The controller has been optimalised to the Mach2 & Mach3 CNC control softwares. The DSP processor enables to choose even a very short Dir selection.

- Because of its professional features the controller has got a strong noise protection, which can be raised to a maximum level by a suitable installation (mounting). The case-mounted version has all these features.

*The Tuning factor: determines the maximum applicable motor power supply voltage for each motor as the function of the base voltage of the motor (Upower=Umotor× Tuning factor).

![]() Installation,

putting into operation

Installation,

putting into operation![]()

(detailed description)

Mechanical build-up, elhelyezés:

PCB:

- Two-sided partly SMD mounted PCB,

- Size of the PCB: 169× 90 mm height min. 50mm (with ventillation),

- 4 boreholes with a diameter of 3.5mm for the fixing screws, distance of the boreholes 159×179.mm spacing.

(PCB)

The Controller can be mounted by setting on the edge, and one can be mounted to the top of the other, so that the possible smallest place could be demanded. Care must be taken of the free ventillation. The optimal buil-up of the controller is a block, where the cards are mounted set on their shorter edge, one is mounted to the top of the other with metal spacers.

(recommended block-type build-up and ventillation)

It must be placed far from (electric) noise sources. By placing it into a case, it will be protected from mechanical effects, dust, but the free ventillation must be ensured. Do not expose it to shock.

In case of motors with nominal current consumption more than 4A/phase forced cooling (by fans) is necessary.

Electric connections, wiring:

All the wires should be shielded mounted

The high-current wires (connection of motor and its power supply) are on a

screwed terminal. The cross-section of the wires is maximum 1.5mm2.

All the high-current wires should be shielded twisted pairs. For this purpose

the so-called industrial 4 - 20 mA signal cable, which is a 4-wire (2 twisted

pairs) shielded with a cross section of 0.5 mm2, is very well suited

(available in special electric shops).

2×2 twisted pairs, with a cross section of 0.5mm2)

(one twisted pair are the 2 ends of 1 motor-coil, and the

shields go to the common GND rail)

According to the shop the cable type is GJY STY and it is available with several cross-sections (0.5mm2 is the suitable).

Care must be taken of the right polarity of the motor connection

(motor power supply). In case of wrong connection the Controller immediately

goes wrong!

The high-current wires should be mounted as fas as possible from the Controller.

The connections of the digital power supply (Power) and those of the signals are lines of pins. The pin-line connections are using standard internal PC (CD-ROM - motherboard), audio (shielded) cables. The usage of such (shielded) cables, with wide black connector at both ends is strongly recommended. The connectors are positioned, reverse connection is not possible.

(Signal connection)

(shielded signal cable)

Care must be taken not to exchange the signal and power line. Wrong connection may cause the Controller to go wrong immediately!

The shield must not be used as active wire (no current must flow through them). All the shielding must be connected to the digital minus pole (GND or M-), (on the terminals of the Signal and the Power connection these happen automatically). Take care of avoiding the formation of ground loops. The high-current wires must be mounted as far as possible from the signal wires.

The wires should not touch (should not be in connection) with the heat sink (danger of melting)!

To a Profi2B (base card)

maximum 4 Profi2M motor controller cards can be connected.

The Profi2B card provides the digital

power supply voltage for the Profi2M Controllers (+5V end +15V), as well as the

amplified Step/Dir signals. Besides that it has 5 inputs and 4 relay outputs (they

can be used freely).

The I/O wiring must be shield-mounted. The high-current wires (motor power

supply wires) should be twisted pairs. As small-signal wires (Signal, Power) the

internal PC audio cable (which is shielded) is recommended (this was designed to

be used).

(Profi2B Base Card)

A letter, A - D must be attached to the each of the 4 Profi2M

Controllers, and the letter attached to the controller should be written onto it

by an alcoholic marker. Later, based upon this marking the bit allocation table

- controller assgination can be performed.

The signal connector of Profi2M must be connected to the signal connector of

Profi2B (upon the denomination)!

The power connector of Profi2M must be connected to the power connector of

Profi2B. Regarding the power supply connections, the marking has no special

importance (they are the same).

Regarding the power supply system, it is possible to apply a

common motor power supply (all the motors have the same power supply), or a

distributed (even separate supply for each axis) power supply system can be

designed (in the later case only the minus terminals of the motors must be

common).

The digital GND (Profi2B) and the minus terminals of the motor power supply must

not be combined outside the Controller (they must be combined inside the Profi2M

Controller).

Before selecting the motor power supply volatge it is recommended to read the Tuning description of Profi2M, which helps to choose the right parameters.

The power supply voltage of the motor does not need to be

stabilised, but filtering with min. 1000uF capacitor/A is necessary (oversizing

the capacitor is not at all harmful, even it is good...)! As loading current the

phase current of the motor should be taken into account (in case of a common

power supply the summerised value for each axis).

At least a tuning voltage of 6-fold is suggested.

Maximum 50V voltage can be switched onto the controller. This value must not

be exceeded! Tkae care of the increased voltage of the unloaded motor.

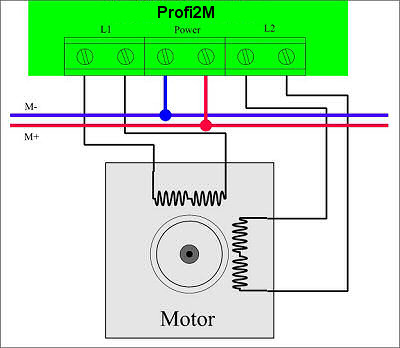

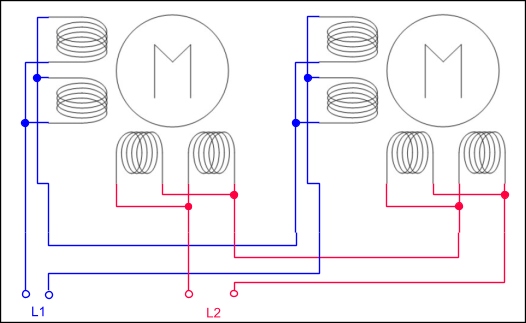

Connections of the Motors:

(connections of the phases of the motor and the power

supply of the motor)

- The Controller was designed to be used with 2-phase, bipolar

(4-wire) motors.

In case of bipolar motors the common phase ends must be connected to SK3 (L1)

and SK2-ba (L2). The power supply voltage of the motor must be connected to SK1

(with the right polarity). The phase order does not matter, in the CNC softwares

the rotaion direction can be changed.

(Connection of bipolar motors)

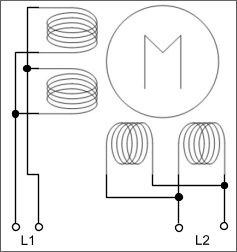

- In case of universal (8-wire) motors it is worth connecting the coils paralell in pairs (paralell connection of the coils belonging to the same phase). In this way higher torque and better tuningability can be achieved.

(Coonection of the 8-wire motors)

In this case the motor current to be adjusted is the double of the coil-current (or of the value indicated in the specifications).

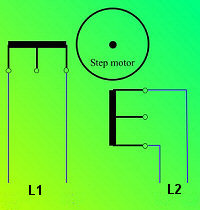

- It is possible to connect unipolar motors too. This can be done in two ways:

|

|

| A | B |

|

(How to connect unipolar motors) |

|

There are important differences between the 2 connection mode.

Mode A : about 20 % higher torque can be achieved at low speed (twice as many windings are excited), but the available maximum speed is a lot smaller (because of the a 2-fold inductivity) at the same power supply voltage. The base voltagem and the inductivity of the motor is twice as much as those given in the specifications. The current to be adjusted is the nominal current of the coil.

Mode B : All parameters are the same as given in the specifications (higher speed, nominal torque). The current to be adjusted is the same that is indicated on the motor (or given in the specifications). It does not matter that within the coil which end is connected to the middle wire of the Controller (it influences only the rotation direction). This is the preferred mode of connection.

- Serial connection and synchronous drive of two motors for an axis can also be realised:

(2 8-wire motors on the same axis)

Only absolutely identical motors are allowed to be serial connected. In this case the resultant motor is a motor with twice as much operation voltage (and inductivity). Its tuningability is poorer than when only one motor is connected.

In case of the application of Mach3 softwares, the logical assingnment of the axes (slave modes) can be solved and the full synchronous driving can be realised, so on the controllers 2-motor drive for each axis with one motor can be realised.

(logical axis assignments)

More information on motor tuning and designing the correct motor power supply can be found in Tuning description.

The power supply of the motors must be protected by suitable

fuses (serial connected with M+).

The digital power supply (on the Profi2B card) is short-circuit-protected.

Ajustment of the motor current (Current trimer):

Before switching voltage to the Controller for the first time , the following steps should be done:

- It should be checked whether the connections are right (their location and polarity) and whether the motor circuit is shortcircuit-free (the Controller is not shortcircuit-protected).

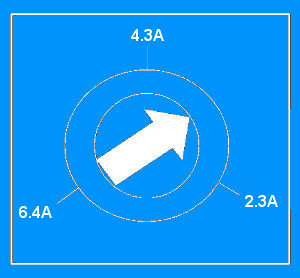

- By the means of jumpers Current A and Current B the current range, in that the nominal current of the motor can be easily adjusted, must be selected.Setup Current= 1.4×RMS!!!

(Current Jumpers)

Jumper posítions:

Adjustable current-range: 1-2

3.2A - 9.0A

3-4

2.3A - 6.4A

(Current ranges of Current trimer)

- It is important that the jumpers of both ranges, (Current A and Current B) must be in the same position.

- By the Current (R25) potentiometer trimmer the nominal current of the motor must be adjusted. By the means of a small screw driver, turn the potentiometer trimmer gently to clockwise direction and observe its end-position. Inn this position the regulator would regulate to the smallest current value.

Then turn the potentiometer trimmer to counter clockwise direction and also observe this end-position. At this point the regulator would regulate to the maximum current value.

Then divide the moving angle and estimate the position which belongs to the current value (motor current×1.4) our motor needs and put the potentiometer trimmer into this position.

|

|

|

|

Jumper: 1-2 |

Jumper: 3-4 |

(Adjustment of the nominal current of the motor: Current trimer)

The controller is not sensitive to the exact adjustment. During operation the position of the potentiometer trimmer can be modified at any time (observing the voice and upwarming of the motor).

- Adjustment of the Stepping system (resolution):

On the DSP Config Jumper-line the stepping resolutionl(micro-step) of the motor can be adjusted.

(Micro-Step Jumps)

Jumper positions: Stepping system: Stepping/revolution:* 1-2; 3-4 One Whole 200 3-4 Quarter 400 1-2 Half 800 - One sixteenth 3200 (Micr-Step table of the DSP Config Jumper-libe.)

*Referring to a motor of 1.8°.

The othe r jumpers adjust internal functions, which are ajusted by the manufacturer. The use of Quarter-stepping is suggested.

Now the Profi2M Controller is ready for CNC operation!

The configuration set-up of the controllers from the PC side can always be found in the documentaiuon of the base card applied (if you use the Profi2B interface card, then its description can be found on this web page). To make the set-up easier, a fast set-up file can be downloaded too.

(The appearance and use of the new prfile after installing the fast Set-up file)The Controller needs Non-inverting Step signals (it makes stepping on the rising edge).

(Motor tuning screen of Mach3)Recommended pulse data: Step Pulse=2, Dir Pulse=2.

Usage:

During nomal operation of the Controller (in Online mode) the

Power OK

LED indicates the normál condition.

The Overdrive

LED indicates overwarming of the Controller (appr. above 70°C) and it will

prohibit its further operation auntil it cools down.

This is a phenomenon referring to overloading or insufficient ventillation.

The excitation of the motors can even be adjusted during operation. Observing the voice of the motors (at relatively low revolutions, e.g. 500 - 1000 steps/sec) the excitation force can be adjusted (the motor will be the smoothest/the most silent, when it operates with the most suitable values).

The speed of the motors, the direction of their rotation and their acceleration (and several other parameters) must be adjusted within the CNC control programme applied (see e.g. the descriptions of Mach3)!

Further additional information can also be found in the description of Profi2M motortuning.