![]() Hobby

CNC Mechanical 1

Hobby

CNC Mechanical 1![]()

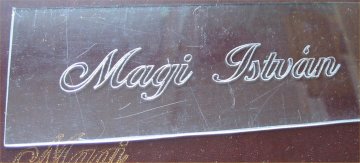

engraving / milling / router

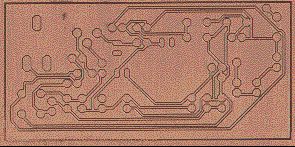

Step/Dir System

Last modification: 05.25.2004

Video (![]() wmv)

2.2MB Video2 (

wmv)

2.2MB Video2 (![]() wmv)

2.1MB Video3 (

wmv)

2.1MB Video3 (![]() wmv)

785 kB

wmv)

785 kB

The mechanical construction described in this guide is made of core-boards, which are the cheapest and most easily machinable materials in the category of hobby machines. Of course this buld-up limits its useage and load capacity. It is not suitable for machining of carbide metals in bulk, but it is excellent for realising hobby works, custom-built things and for studying. This construction is only one of the possible „Hobby CNC” solutions. If someone has the necessary resources (place, tools and skill), it is better to realise a construction made of metal.

Specifications of my Hobby CNC

machine:

Resolution: 0.00625 mm/Step (Profi Firmware); 0.0125 mm/Step (Hobby Firmware)

Maximum machining dimensions: X=300 mm; Y=280 mm; Z=100 mm.

Maximum inching speed: ~ 450 mm/minute.

Tool revolution: ~ 20,000 revs / minute.

Tool power: 40 W.

Machine control: via PC (KCam4 Hobby CNC Controller , Master5 CNC , etc.

under WindowsXP; TurboCNC under DOS).

Motorcontrol: precision Step/Dir system, software control via PIC (independent

hybrid/native PWM, intelligent setup, tuning, error detection, etc.)

Examples for application:

My Hobby CNC machine is made of core-boards. Its slides are

precision drawer-rail rollers made in Germany, (absolutly clearance-free steel

roller bearing system). Driving: by an M8 screwed shank with internal spring

tensioning mechanism.

Motors: demounted from old GDR-made ROBOTRON printers, 24V, unipolar,

6-terminal, 1.2 A/phase, 3.6 o/Step-resolution stepping

eletromotors.

There are a lot of small things, which cannot be seen from outside, but

everything can be obtained. The mechanic assambly can be set up in a relatively

cheap way, - comparing to a CNC machine. Core boards give a good mechanical

stability and flat surface, which can be machined easily.

As absolutely perfect manufacturing cannot be done in amateur conditions, there

have been designed as many adjusting possibilities as possible, such as clutch,

bearing-adjusting possibility, shaft angle, etc.

The body was realized with the most efficient room

utilisation.

Before trying out the machine in real conditions ttest drawings can be made by

the means of an own-developed ball-pen.

HALL device-bush-buttons take care of the detection of end positions.

Fotos:

The upper fastening plate can be detached from the lower carrier fluted plate and it can be exchanged for another bolster without the need of grooving each bolster.